Mayonnaise Jar from Australia

Shrink Sleeves not only can seal products, but also can act as label and promotion tool, therefore automated sleeve applicato is needed to help the production line be faster and efficient.

Benison offers different types of sleeving applicators that can fulfill different demands. Benison also can give solutions and provide all the required materials and equipment, including selections of packaging materials, machines and packaging line, etc. Benison team is ready to help you by giving customized solutions with professional service to increase production efficiency.

Solutions below can be changed basing on the actual product size and output requirements. You are welcome to contact us for consultation.

Sleeving machine LG-150(CE) for Mayonnaise Jar from Australia Products Solutions

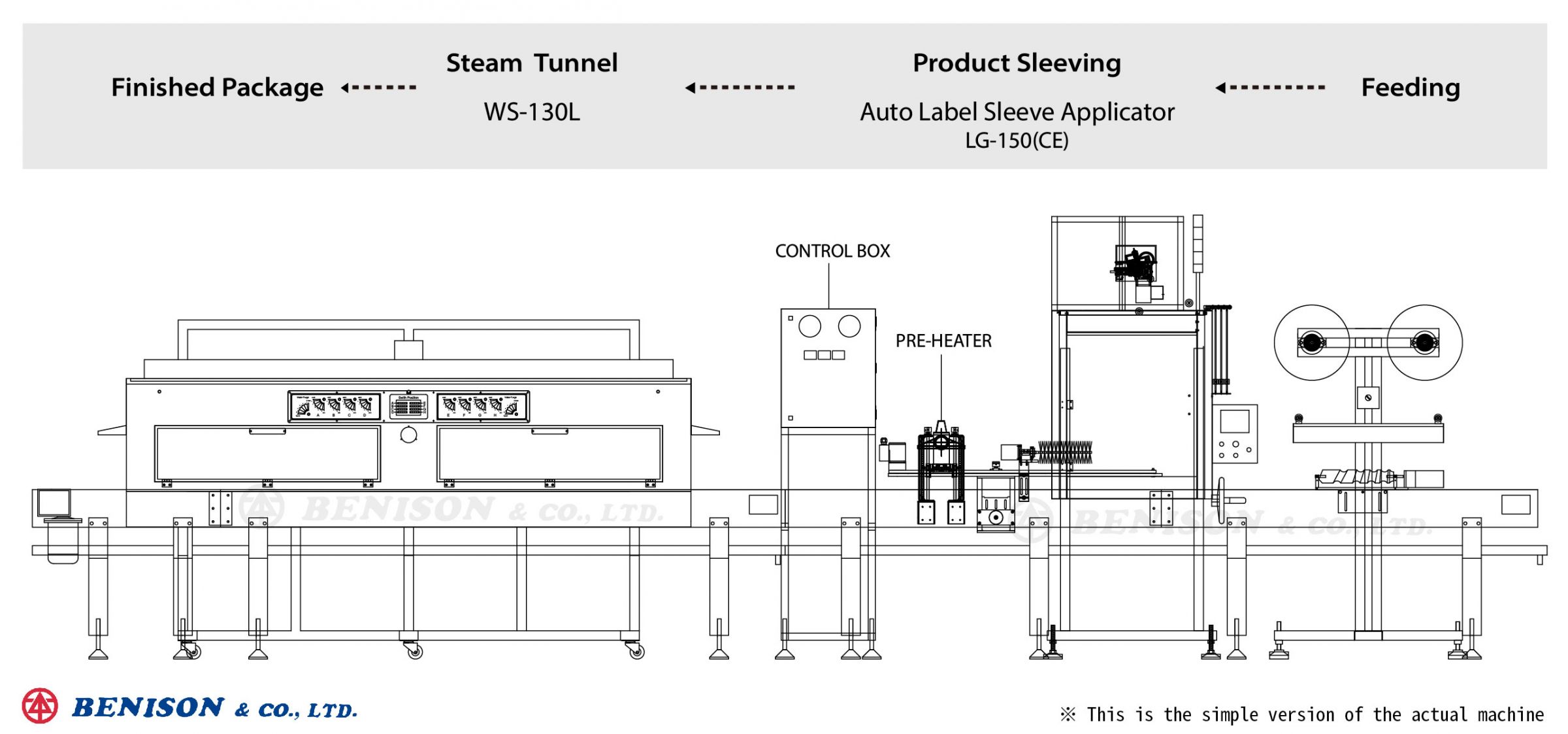

Auto Label Sleeve Applicator, LG-150(CE)+ Steam Tunnel,WS-130L

A multinational company from Australia came to ask Benison help them find automated machine to seal the cap of mayonnaise bottle jar. They sent us two glass bottles, size 600gram and 400gram, to evaluate. After reviewing this case, Benison recommended packaging line (Sleeve Applicator LG-150(CE) with Steam Tunnel WS-130L) to perform cap sealing for the jar. Cap Seals or Tamper Evident Seal can protect and ensure product quality before use. Using the automated machine to apply cap seals can increase the efficiency production line; moreover, it can minimize the contamination risk compared to manual works.

Material

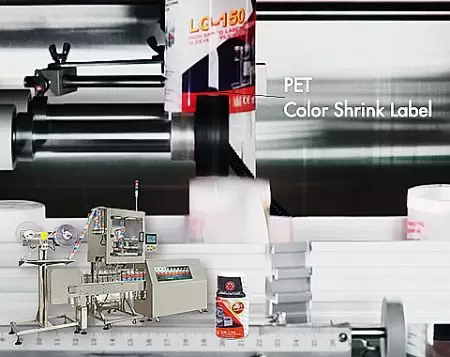

PVC seamless material is used to seal the cap of the jar. PVC film has characteristics of high durability and resistance to damage. It can give excellent protection to products.

Equipment

Sleeving applicator LG-150(CE) is able to run up to 250 bottles per minute. The company asked the production line from right to left to meet their factory layout. For this temper evident case, we added pre-heat guns to heat both sides of the cut shrink sleeve before coming into Steam Tunnel WS-130L, ensuring the film will not swift during shrinking. Our technical team also equipped a perforation device on Sleeving Applicator LG-150(CE) to make perforation line on shrink sleeve before being applied to the machine. Later, this perforation line on the materials can help the customer easily tear off the seals when opening the bottle. The company also requested safety-function mode that makes the production line shut down automatically when the safety door is opening during machine running. Besides, this machine can work for different sizes of bottle with easy adjustment.

Overall, This packaging solution is for applying tamper-evident seal to mayonnaise bottle cap. In the end, Sleeving applicator LG-150(CE) with Steam Tunnel WS-130L can help the company seal their product and ensure the product quality more efficient!

Machine Specifications

- Auto Label Sleeve Applicator LG-150(CE)+Steam Tunnel,WS-130L

- Speed: 250/BPM

- Output: Temper Evident Cap Seal

Features

- CE certified

- HMI can support smart factory and memories working settings that can save operator time

- Able to apply material in different sizes of cap bottles with easy adjustments

- Support high production line

- Suitable for food and non-food industries

- All machinery and equipment comply with food safety production regulations

- The equipment, material, and quantity can be adjusted based on actual production needs

- Benison can provide consultation about plant layout planning, production line optimization, and labor allocation.

How To Get A Solution Proposal?

Any problems or questions are welcome. Do not hesitate to contact us by enquiry form below or our hotline service. Benison professional consultant team will evaluate your existing plan and expected output product. In addition, Benison team will arrange further contacts in order to understand your needs.

- Movies

- Gallery

- Related Products

- Files Download

Recommendation of popular products, please see the product introducing pages for more details.

Mayonnaise Jar from Australia | Global Leader in High-Efficiency Packaging Machines and Materials

Established in 1962 and based in Taiwan, Benison & Co., Ltd. is a leading supplier of packaging solutions. We specialize in shrink packaging, heat shrink films, tamper-evident bands, and automated packaging machines for the food, beverage, pharmaceutical, and industrial sectors. Our products include horizontal flow wrappers, auto label sleeve applicators, and over-wrapping machines, all designed to enhance production efficiency and reliability.

Our expertise spans both packaging machinery and film production, offering industry-leading technology and eco-friendly solutions. Advanced heat shrink packaging machines and automatic shrink wrap systems ensure high efficiency and reliability for various industrial applications. Sustainable shrink films provide excellent product protection and presentation. Focused on innovation and comprehensive customer service, we attract international buyers seeking top-quality and reliable packaging solutions, reinforcing our position as a global leader in the packaging industry.

Benison has been offering customers high-quality heat shrink packaging and shrink wrap machines, both with advanced technology and 60 years of experience, Benison ensures each customer's demands are met.